The next generation in pipe lining coatings

Resiline Spray in Place Pipe (SIPP) linings have been developed by Industry leading experts and extensively tested to demonstrate fitness for purpose for the rehabilitation of aging and deteriorating potable and non-potable water pipelines.

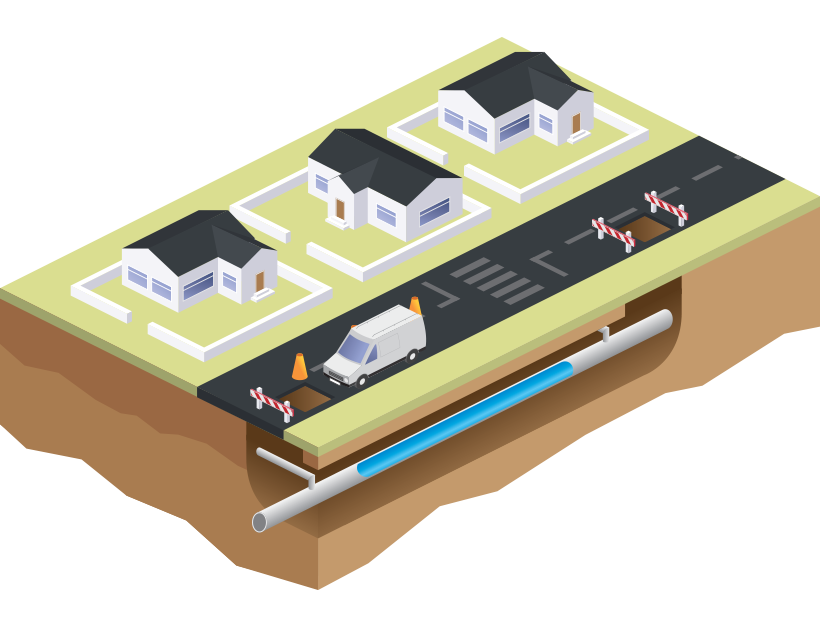

Spray in Place Pipe (SIPP) lining using Resiline materials offers a cost-effective trenchless technology to resolve pipeline integrity issues, restore flow and pressure, minimise network leakage and increase resilience and reliability.

Resiline materials can be applied as AWWA Class I, II, III or IV linings and same day return to service can be achieved, minimising disruption to the water supply.

SIPP lining with Resiline also significantly reduces Carbon Footprint by up to 80% compared to replacement.

High Creep Strength

For long-term exposure to pressureHigh Tensile Strength

For long-term pressure containment capabilityHigh Wet Flexural Modulus

To avoid collapse under vacuum or external pressureLow Water Absorbtion

Critical to avoid plasticisingDiscover More

Why use a pipe lining material?

In situ pipe lining or spray in place process (SIPP) has many benefits in comparison to traditional pipe renewal methods.

When used with approved in situ pipe coating and spray application equipment, Resiline materials provides a quick, reliable and long-term solution.

- Rapid-setting lining

- Cost effective & efficient solution

- Reduced disruption to road users and pedestrians due to the minimal excavation technique

- Service pipes to individual properties are not affected as there isn’t the requirement to dig these up and reconnect them

- Reduction in noise, dust and carbon emissions.

Learn more about the key innovations which set Resiline materials apart from any other product which has gone before

Drinking and Potable Water Pipelines

Sewer, Wastewater and Non-Potable Water Pipelines